Shenzhen Vencore Electronics Co., Ltd.

Tel: 0755-27267961

Email: sales@vencorepcb.com

Website: www.vencorepcb.com

Address : Buildings 221 and 226, Dazheng Technology Park, Jiangbian Industrial Road 6, Songgang Street, Bao'an District, Shenzhen

Building 2, No. 119 Changmao Road, Changzhen Community, Yutang Street, Guangming District, Shenzhen

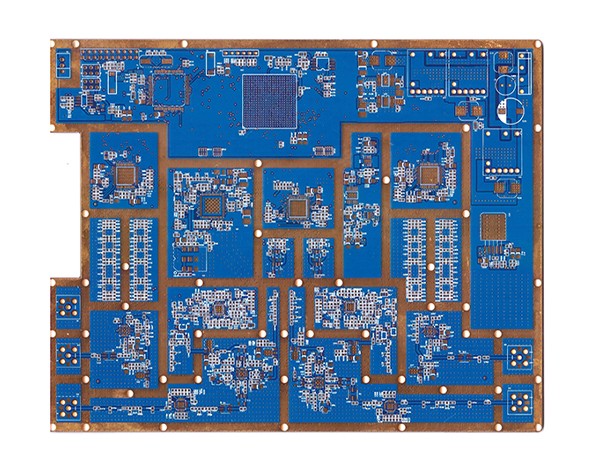

In the process of PCB circuit board design or production, the circuit board may be short-circuited due to operational errors or other reasons. If a circuit board is shorted, the first thing to do is to find the cause to fix the problem. How to check the cause? Let's take a look with me~

1. Open the PCB design diagram on the computer, light up the short-circuited network, and see where is the closest and easiest to connect. Pay special attention to short circuits inside the IC.

2. If it is manual welding, develop a good habit:

1. Before welding, visually check the PCB board, and use a multimeter to check whether the hub circuit (especially the power supply and ground) is short-circuited;

2. Use a multimeter to check whether the power supply and ground are short-circuited every time the chip is soldered;

3. Do not throw the soldering iron at will when soldering. If you throw solder on the solder legs of a chip (especially surface mount components), it's not easy to find.

3. Find a short circuit. Take the board tangent (especially suitable for single / double board). After the tangent, the function blocks of each department are powered on and eliminated step by step.

4. Use a short-circuit position analyzer

5. If there is a BGA chip, because all the solder joints are covered by the chip and invisible, and it is a multi-layer board (more than 4 layers), it is best to separate the power supply of each chip when designing, and use magnetic beads or 0 ohm resistors to connect , so that when the power supply and the ground are short-circuited, the magnetic bead detection is disconnected, which is convenient for locating a certain chip. Because BGA soldering is difficult, if it is not automatically soldered by machine, the two adjacent power supply and ground solder balls will be short-circuited if you are not careful.

6. Be careful when welding small-sized surface mount capacitors, especially the power supply filter capacitors (103 or 104), which may easily cause a short circuit between the power supply and the ground. Of course, sometimes the fate is not good enough, and the capacitor itself will short-circuit, so the best way is to test the capacitor before soldering.

PCB circuit board short circuit inspection can basically find the reason through the above six points. If you have anything else you don't know, you can ask our engineers to answer it for you~

Copyright © Shenzhen Vencore Electronics Co., Ltd. Number:粤ICP备2021150348号