Process capacity Monthly production capacity: 15,000 square meters (multilayer board)

Layers: 2-36 layers

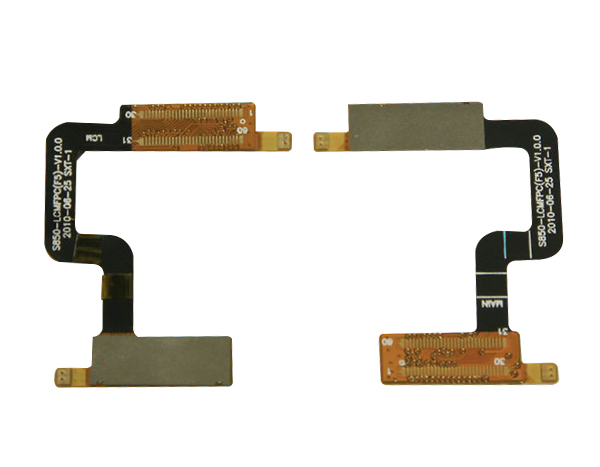

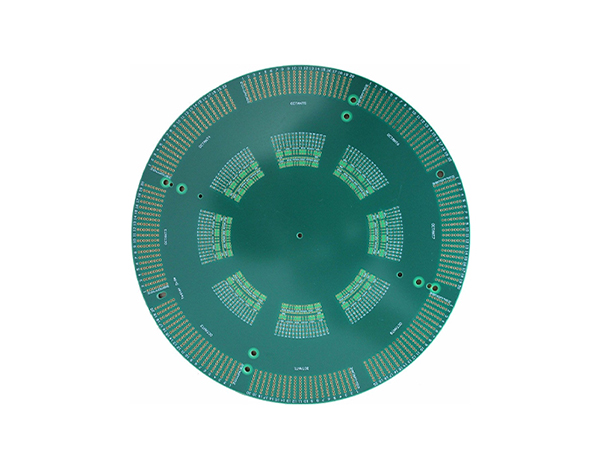

Product type: HDI board, high frequency board, RF board, impedance board, thick copper board (7 OZ), flexible and rigid board, yin and yang copper board, aluminum substrate, mixed pressure board, backplane, buried capacitance and buried resistance board

Raw materials:

Conventional sheet: FR4 ( Shengyi S1141, Kingboard KB)

High Frequency Materials: Rogers, Taconic, Arlon

High TG sheet: S1000-2M, Lianmao IT180A and supporting P sheet

Halogen-free sheet: Shengyi S1155, S1165 series,

Solder mask: Sun ink (Japan Taiyo PSR-2000/4000 series)

Chemical potions: Atotech browning potion (MS300), Rohm and Haas electroplating potion (125T, EP1000), etc.

Surface treatment: spray tin, lead-free spray tin, immersion gold, OSP, immersion tin, immersion silver, hard gold plating (50u”)

Selective surface treatment: Immersion Gold + OSP, Immersion Gold + Gold Finger, Immersion Silver + Gold Finger, Immersion Tin + Gold Finger

technical parameter:

Minimum line width/spacing: outer layer 2.0/2.0mil (complete copper thickness 30um), inner layer 2.5/2.5mil (1/3, 1/2OZ)

Minimum drilling: 0.15mm (mechanical drilling)/0.1mm (laser drilling)

Minimum Solder Ring: 4mil

Minimum interlayer thickness: 2mil

Thickest copper thickness: 18 OZ

Maximum size of finished product: 600x800mm

Board thickness: double-sided 0.2-7.0mm multi-layer board: 0.4-7.0mm

Solder mask bridge: ≥0.08mm

Plate thickness aperture ratio: 26:1

Plug hole capacity: 0.2-0.8mm

tolerance:

Metallized hole: ±0.075mm (limit ±0.05)

Non-metallic hole: ±0.05mm (limit +0/-0.05mm or +0.05/-0mm)

Outline tolerance: ±0.1mm (limit ±0.05-0.075mm)

function test:

Insulation resistance: 50 ohms (normal)

Peel strength: 1.4N/mm

Thermal stress test: 280 ℃, 20 seconds

Solder mask hardness: ≥6H

Electrical measurement voltage: 10V-250V

Warpage: ≤0.7%