Shenzhen Vencore Electronics Co., Ltd.

Tel: 0755-27267961

Email: sales@vencorepcb.com

Website: www.vencorepcb.com

Address: Building A5, Tongfuyu Industrial Park, Daxing 2nd Road, Shajing Street, Baoan District, Shenzhen

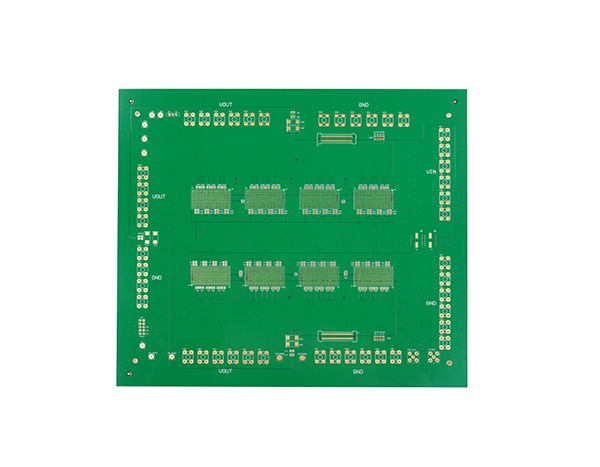

PCB circuit board is an integrated body of electronic product components. The main function is the carrier of the electrical interconnection of electronic components. It is made by electronic printing. What should be paid attention to when designing a pcb circuit board? Let's take a look with me~

Avoid pad overlap when designing pcb boards

1. Overlap of pads (except surface mount pads) refers to the overlap of holes. During the drilling process, due to multiple drilling in one place, the drill bit can break, resulting in hole damage.

2. The two holes on the multilayer board overlap. For example, one hole is an isolation disc, and the other hole is a connection pad (flower pad), so that after the film is pulled, an isolation disc will appear in the film, resulting in scrap.

computer circuit board

PCB circuit board design to avoid abuse of graphics layer

1. Some graphics layers make some useless connections. It turned out that the four-layer board was designed with more than five layers of wiring, which caused a misunderstanding.

2. Save the trouble of design. Take Protel software as an example, use the Board layer to draw lines on each layer, and use the Board layer to mark the lines. In this way, when performing light drawing data, the board layer is not selected, and the connection is omitted. The integrity and clarity of the graphics layer was maintained during the design due to broken, or shorted, lines due to the choice of label lines for the Board layer.

3. Unconventional designs, such as the component surface design of the Bottom layer and the welding surface design of the Top layer, cause inconvenience.

Arbitrary placement of pcb circuit board design words

1. The SMD pad of the character cover pad brings inconvenience to the continuity test of the printed board and the welding of components.

2. The character design is too small, resulting in problems with silk screen printing, and too large will cause the characters to overlap each other and be difficult to distinguish.

PCB circuit board design should pay attention to the setting of single-sided pad aperture

1. Single-sided pads are generally not drilled. If the drill hole needs to be marked, the hole diameter should be designed to be zero. If this value is designed, when the drilling data is generated, the coordinates of the hole will appear at this position, and there will be problems.

2. If there is a drill hole on the single-sided pad, it should be specially marked.

Use filler blocks to draw pads when designing pcb boards

Drawing pads with filler blocks can pass DRC inspection when designing circuits, but are not conducive to processing. Therefore, similar pads cannot directly generate solder mask data. When solder mask is applied, the area that fills the block will be covered with solder mask. Difficulty in soldering the device.

Pay attention to the above aspects when designing a pcb circuit board, otherwise it will cause various problems. Yongjiafeng circuit board manufacturers have many years of industry production experience and rich experience in circuit board design and production. If you have any questions, please contact us~

Copyright © Shenzhen Vencore Electronics Co., Ltd. Number:粤ICP备2021150348号